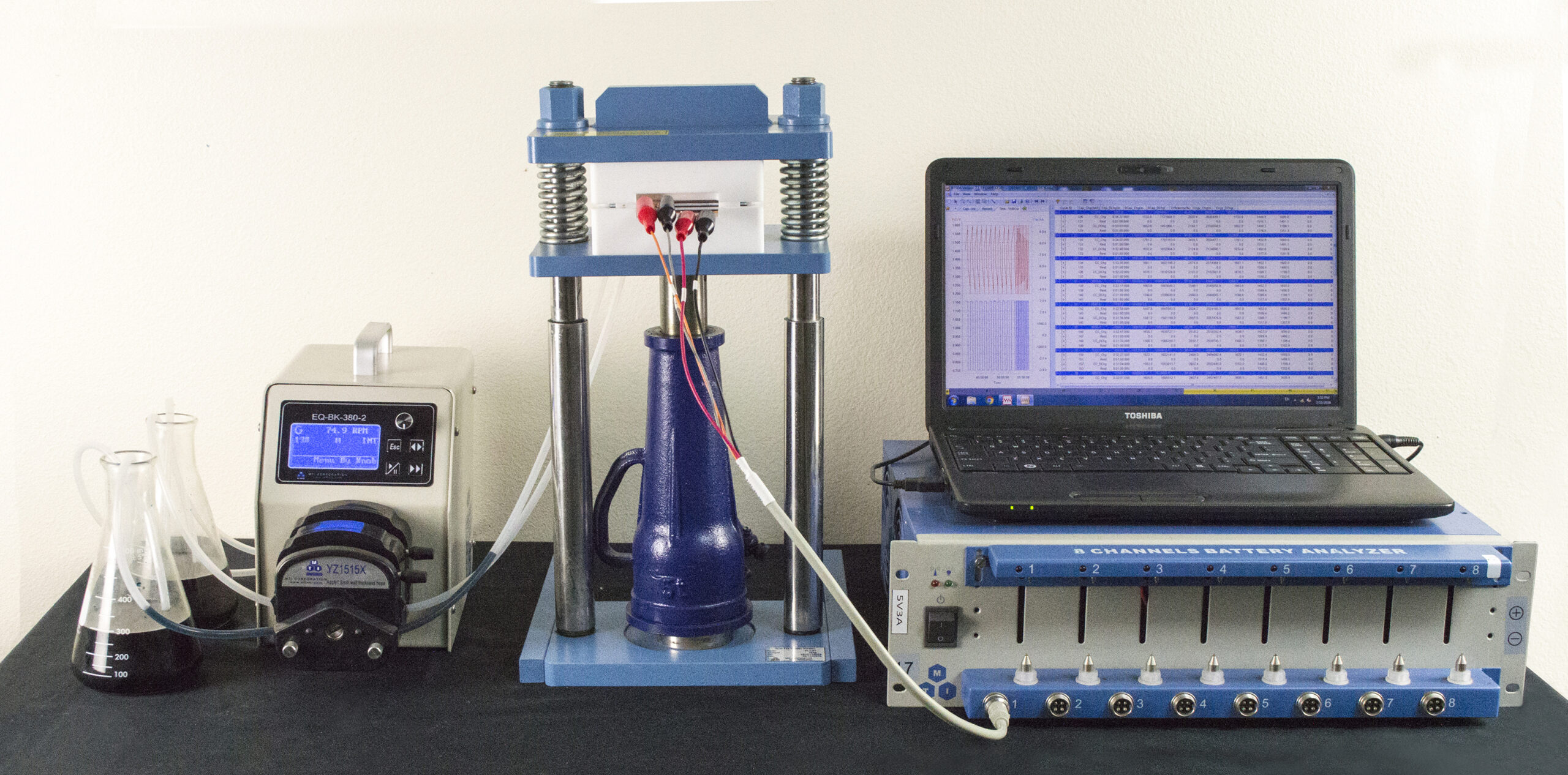

EQ-VRB-C is a splitable single unit flow cell for Vanadium Redox Flow Battery research. This split test cell features easy and fast assembly with convenient part replacement to facilitate research for flow cell cathode and electrolyte solutions.

- Single cell voltage range: 1.2V ~ 1.6V (depending on Vanadium electrolyte composition)

- Cell current density: 40 ~ 100 mA / cm2

- Manifold Blocks are made of anti-corrosive PTFE materials to withstand acids

- Cathode materials are changeable according to the test conditions

- Easy assembly and disassembly

Complete testing package together with Mechanical Jig for preventing electrolyte leakage, dual channel peristaltic pump, battery analyzer and electrolyte container.

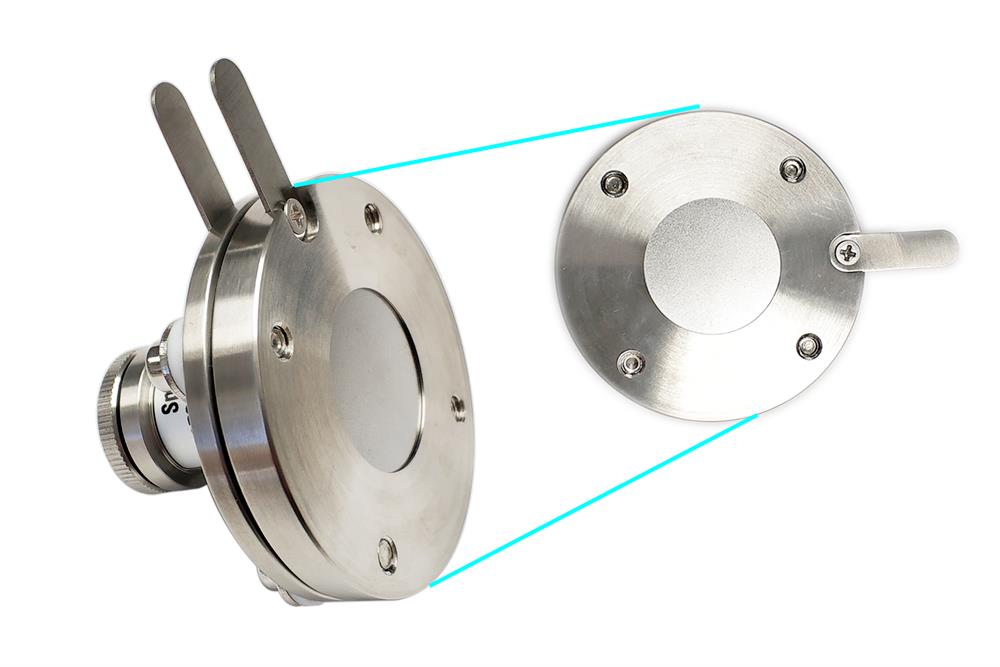

EQ-3ESTC split test cell is designed for R&D of rechargeable battery materials by . Two sides of the test cell connect to both electrode (the anode and cathode), with the middle being connected to the reference electrode which can be used for monitoring voltage variations of the two electrodes. This test cell can accept 15 mm diameter electrodes and 24 mm separators.

This is a three-electrode with dimension of cathode/anode and reference ring as the follow:

- Cathode disk : 15 mm diameter or less

- Anode disk : 15 mm diameter or less

- Li Reference ring : 26 mm OD* x 19 mm ID**

- Air-tight sealed by electrolyte corrosive-proof O-rings is included

- Electrolyte corrosive-proof PTFE Guide Sleeve capable of withstanding up to 250 °C is included.

- The adjustable spring tension on top to accept various electrode thicknesses is included

- Glove box compatible

- 3 different materials structure :

| Item Number | EQ-3ESTC-Al | EQ-3ESTC15 | EQ-3ESTC15P |

| Structure | Aluminium Alloy: LY12 (dedicated to using at high voltage > 4.5V) | Full stainless steel SS304 | SS304 with Digital Pressure Gauge |

- Optional : MSK-T-13 disc cutter is needed to cut all electrode disc, including a ring-shaped reference electrode (26 mm OD x 19 mm ID)

EQ-STC-BEW split test cell features a 35 mm diameter Beryllium (Be) Window which allows in-situ XRD analysis of battery material phase transitions during the charging/discharging cycles. Such a cell can accommodate various sizes (19, 20, and 24 mm diameter) of electrodes and separators.

- Stainless Steel constructed body and pressing plate

- Beryllium (Be) Window that allows the X-Ray beam penetration

- PTFE Sleeve

- PTFE O-rings

- SS Hex Screws

- Height: 47 mm min. without load

- Diameter: 64 mm (diameter without lead)

- Lead-exposed length: 12.6 mm

- Beryllium (BE) Window: 35 mm Dia. x 0.15 mm thick

- XRD Diffraction Angle (2θ) for 20 & 24 mm I.D. Sleeves: 5 ° ~ 170 °

- Maximum working Temperature 250 °C

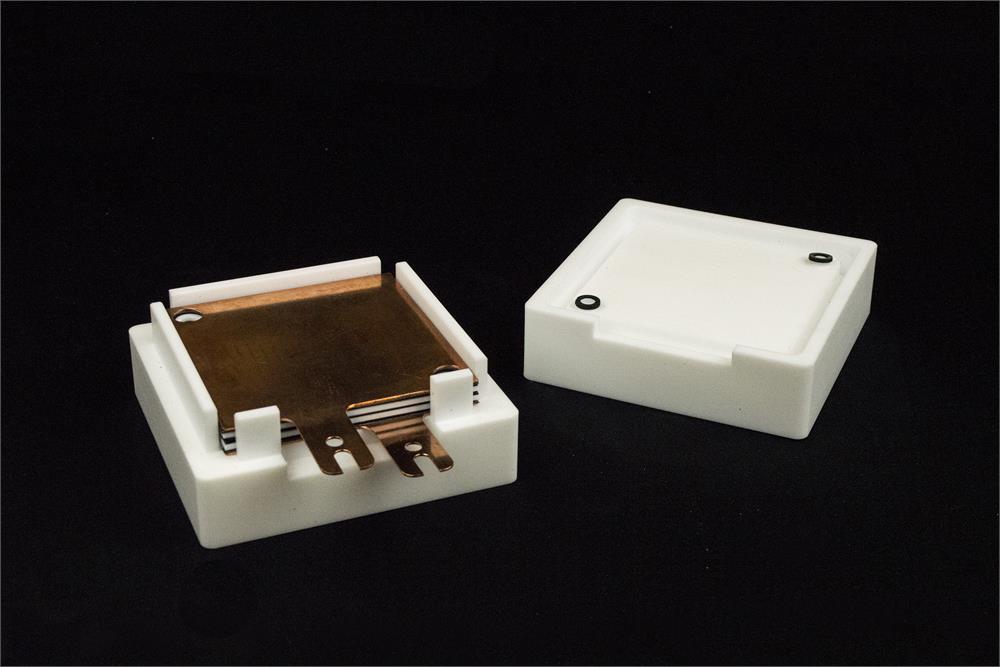

EQ-HSTC is an easy handling “Swagelok type” split cell. It is designed for high-throughput R&D battery material testing without any crimper. It can be used for both liquid and solid-state .

- Stainless Steel contact plate and plunger.

- The Body is made of PTFE body

- Working temperature : ≤ 100 °C

- Airtight design

- Spacer included

- Extending rod included for each electrode

- Fluorine rubber O-ring :

ensure no liquid electrolyte leaking

anticorrosion property in regular battery electrolytes

- Spring :

Material : SUS304***

Spring Rate : 7.9 N/mm

Free Dimensions : 5 mm OD x 3.4 mm ID

Length under maximum compression : 7.2 mm

- Standard maximum diameter that can be put inside : 20 mm

- Maximum thickness of the material that can be inserted : 6 mm

- Optional : Au coating on the base contact plunger and inserts

- 3-Electrode version : EQ-HSTC-III

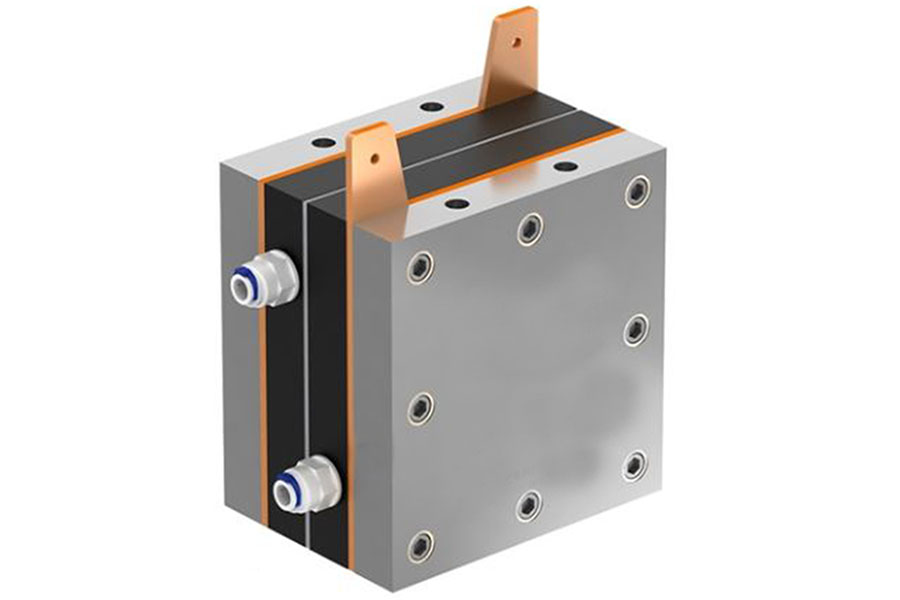

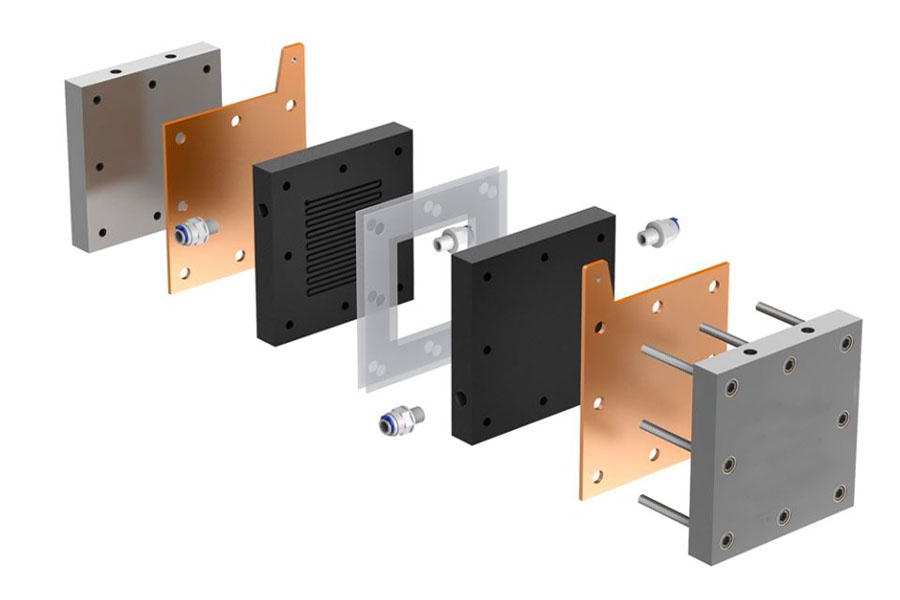

EQ-MEA-MFC is a split electrochemical cell with Membrane Electrode Assembly (MEA) structures for low temperature proton- or anion- exchange membrane fuel cell testing.

- The whole electrochemical cell was made by high purity titanium (Ti) metal for support and protection, copper plates as current collector, and graphite plates with serpentine channels for gas flow and diffusion.

- PTFE gaskets with high electrochemical corrosion property was used to hold the MEA with a sandwich structure.

- Flow Channels with serpentine shape is used for increasing reaction retention time. Flow channels with other shapes are also available upon request, such as parallel, vein type.

- Channel area: 2 x 2 cm

- Fitting tube for inlet and outlet ports : 6.35 mm OD

*OD : Outside Diameter

**ID : Interior Diameter

***SUS : Steel Use Stainless, Japanese Standard JIS