Découvrez comment le TOPEM20 révolutionne le processus de production des batteries à l’état solide grâce à sa technologie avancée de revêtement par impression 3D. Découvrez ses principales caractéristiques et ses avantages, et comment il améliore l’efficacité et la précision de la fabrication des batteries.

Discover how the TOPEM20 revolutionizes the production process of Solid-State Batteries with its advanced 3D printing coating technology. Learn about its key features and benefits, and how it enhances efficiency and precision in battery manufacturing.

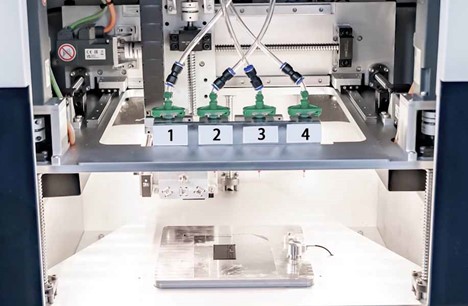

TOPEM20 is a four-nozzles integrated battery 3D printing equipment with 10µm level ultra-high manufacturing precision.

The TOPEM20 3D printer utilizes slurry extrusion lamination technology (SEL) to print battery slurry. It is capable for a wide range of printing materials, including:

- lithium cobalt oxide LiCoO2 cathode slurry

- lithium iron phosphate LiFePO4 cathode slurry

- high nickel ternary cathode NCM8 11

- graphite anode slurry

- polymer solid electrolyte

- polymer

- oxide composite solid electrolyte

- others

The TOPEM20 3D printer boasts ultra-high manufacturing precision of 10µm. Equipped with intelligent integrated micron-level laser sensors and an automatic leveling system, it can achieve high-precision printing of complex-structured electrode layers and electrolyte layers while ensuring the integrity of each layer. It enables the rapid printing of special thick electrodes with continuous microchannel and microporous structures using positive and negative electrode materials. This capability plays a crucial role in enhancing battery performance and provides a broader scope for innovation.

Specifications:

| Features | · 10″ Touch Screen Panel supports multi-languages

· The final product is directly generated from the digital model · Porous structures or any complex geometries can be created as needed · Slurry Extrusion Lamination (SEL) technology with rapid spraying and stacking slurry · um level detector function to achieve 10um stable printing · Equipped with a μm-level layer thickness detection for stable printing of electrolytes |

| Working Voltage |

|

| Max. Coating Area |

|

| Nozzles |

|

| Slurry Visocity | Any kinds of anode, cathode, and electrolyte slurries with appropriate solid-content and viscosity. We have demonstrated the following slurry for battery fabrication.

|

| Printing Software |

|

| Input Format |

|

| Output Format |

|

| Compatible Software |

|

| Compressed Gas Requirement |

|