L’évolution rapide de la technologie des batteries a mis en évidence l’importance de la préparation des électrodes sèches, offrant une densité énergétique plus élevée, un impact environnemental réduit et une efficacité améliorée, qui gagne rapidement du terrain parmi les chercheurs et les fabricants. À l’avant-garde de cette transformation se trouve le MSK-BPC-DF200, une presse à laminer avancée conçue pour simplifier et optimiser la préparation des électrodes sèches.

Benefits of Dry Electrode Technology

Dry electrode preparation eliminates the need for solvents, which are traditionally used in wet electrode manufacturing. This brings several advantages:

- Cost Reduction: Lower material and energy costs due to the elimination of solvent recovery systems.

- Eco-Friendly Process: Reduced chemical usage minimizes environmental impact.

- Enhanced Performance: The absence of residual solvents improves electrode integrity and longevity.

Applications of Dry Electrode Technology

Dry Electrode Technology is suitable for a variety of applications, including:

- Lithium-ion batteries for electric vehicles (Evs)

- Solid-state batteries

- High-power energy storage systems (Supercapacitors etc.)

Key Features of MSK-BPC-DF200

The MSK-BPC-DF200 stands out with its precision engineering and user-friendly design. Below are some of its defining features:

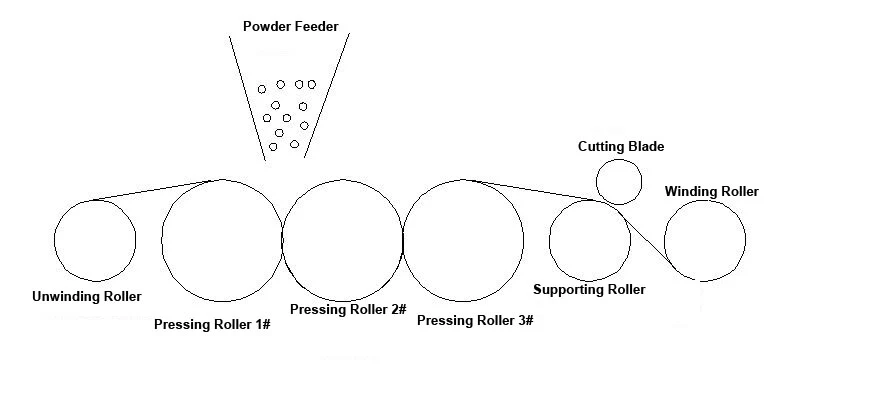

- Three rollers are arranged horizontally, with independent pressure control, independent temperature control, independent electric roller gap adjustment and independent speed adjustment.

- Electric heating roller: The patented electric heating rollers with precise temperature control and good uniformity.

- The patented hydraulic balance rolling mechanism has stable pressure output and pressure maintenance.

- The roller gap is automatically adjusted by the stepper motor.

- The tension is small to prevent the strip from breaking or being stretched after forming.

- It has a built-in trimming function.

- The roller is made of special steel, with a segmented intelligent heating system, which can be heated up to 150°C, and the hardness attenuation is less than 5%.

Specifications

Power:

- AC220±10%, single phase, 50/60Hz

- 3KW

Rollers:

- Roller materials: Hardening Cr12MoV

- Roller size: Ø150 mm x 220 mm

- Hardness: HRC 58-62

- Roller Gap: 0 – 2.5 mm

- Gap accuracy: ± 2.5 um

Working Mechanism:

Roller Temperature: 200°C Max., each roller temperature can be adjusted independently

Maximum Electrode Width: 200mm Max

Rolling Pressure: 8T Max., each roller pressure can be adjusted independently. Applied force resolution: ±0.30Kg

Rolling Speed: 0.3- 2 m/min, each roller speed can be adjusted independently

Recommended Working Environment: 25 ± 3°C, no vibration or electromagnetic interference

Compliance: CE Certified