What is Cold Isostatic Pressing?

Cold isostatic pressing is a process where materials are compacted uniformly under high pressure at room temperatures. Unlike hot pressing, cold pressing prevents thermal damage, ensuring that material properties remain intact while achieving precise and consistent results. Compared with uniaxial pressing, where pressure is applied from one direction, CIP allows for even distribution of pressure in all directions.

Industries benefiting from cold isostatic pressing:

- Aerospace components manufacturing

- High-performance ceramics manufacturing

- Powder metallurgy and composite materials

- Precision electronics and semiconductors

- Medical implants and prosthetics

Key Benefits of Cold Isostatic Pressing

Preserves Material Properties – Cold processing avoids thermal stress, maintaining material strength and microstructure.

High Precision and Uniformity – Uniform pressure distribution ensures consistent density and flawless finishes.

Cost and Energy Efficient – No heating required, reducing energy consumption and operational costs.

Reduced Waste and Cost Efficiency – Optimal material utilization reduces production costs and minimizes scrap.

Flexible and Scalable – Suitable for various materials, including metals, ceramics, and composites.

Leading Cold Isostatic Press Models

We’re proud to offer a series of cold isostatic presses to meet a wide range of researchers’ needs:

YLJ-CIP-15

– The smallest cold isostatic pressing (CIP). Isostatic pressure up to 400 MPa via 15T hydraulic press. Max sample height 70mm. Compatible with glovebox.

YLJ-CIP-20B

– Compact and efficient. Excellent tool for the material research lab to prepare high-density compound samples at ease. Isostatic hydraulic pressure up to 330 MPa via a 24T manual hydraulic press. Compatible with glovebox.

YLJ-CIP-500M

– Compact and efficient. For preparing high-density compounds and ceramics. Isostatic hydraulic pressure up to 500 MPa. Two sets of the CIP vessel and press are available: 30 mm vessel with 40T press and 50 mm vessel with 40T.

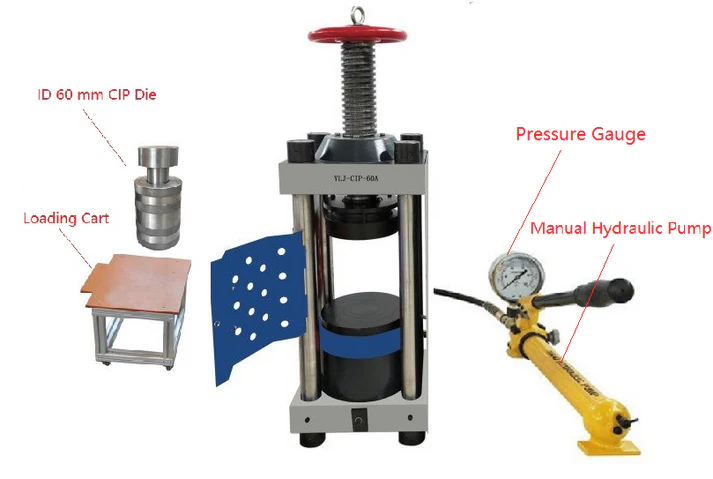

YLJ-CIP-XXA

– Electric cold isostatic pressing (CIP) machine. For preparing many high-density ceramic rods, disks or targets. Isostatic hydraulic pressure up to 900 MPa via a 100T electric hydraulic pump. Optional 35. 50, 60, 80mm ID CIP vessel. Moving cart is included.

YLJ-CIP-200

– Electric cold isostatic pressing (CIP) machine. For preparing many high-density ceramic rods, disks or targets. Isostatic hydraulic pressure up to 400MPa via a 200T electric hydraulic pump. Optional 60, 80, 110mm ID CIP vessel. Moving cart is included.

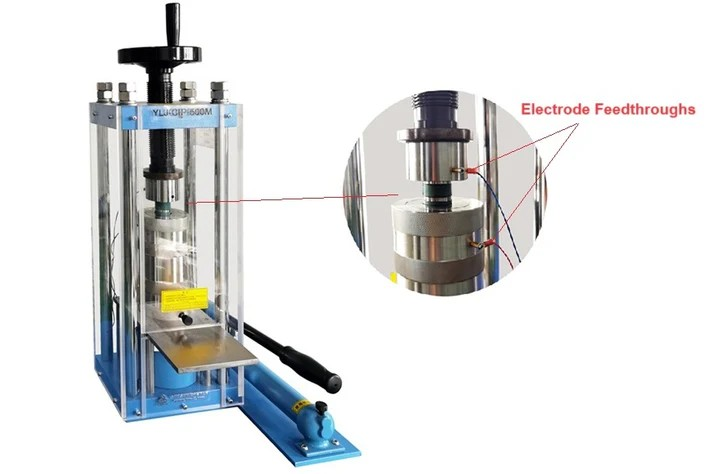

YLJ-CWIP-300

– Manual hydraulic isostatic press with two electrode feedthroughs. Isostatic hydraulic pressure up to 300MPa. WIP die (Warm isostatic pressing) is available. Max. working temperature 90 °C. Heating tape and a digital temperature controller are included.

Each model is equipped with a protection cover and precise pressure gauge or controller. Various vessels of different dimensions and pressures are available for replacement. We could also provide the Vacuum Sealer for sample packing before CIP process.

Thank you for staying tuned in our monthly newsletter.

For more information, visit https://accessr-energy.eu or contact our sales team at contact@accessr-energy.eu